With many different types of sandpaper available, you'll want to choose the right one depending on the DIY job you're working on, whether it's sanding walls, wood, or metal.

When choosing sandpaper, you’ll first want to consider the grit. Grit refers to the size of the abrasive materials on the sandpaper. The lower the grit number, the coarser the sandpaper will be - and the more suited it is to tougher jobs. The higher the grit number, the smoother the finish. The type of abrasive material you use will also impact the quality of the finish, and some abrasives are better suited to certain sanding tools like belt sanders than others.

Once you’ve chosen your abrasive and grit, keep an eye on the backing. You’ll find different materials including cloth, paper or PET film backings – but the crucial thing is to ensure it’s suitable for the abrasive, or they could separate and you could damage your project.

Sandpaper Grit Explained

Sandpaper grit simply means many of each particle of abrasive can fit through a 1 inch mesh filter. For example, a 40 grit sandpaper has large particles, so 40 particles can fit through the mesh filter – whilst 600 grit sandpaper has much smaller particles, so more can fit through.

Using a sandpaper that’s too coarse could make your surface too rough for painting or you might sand away detailing on furniture. Meanwhile, sandpaper that is too fine for the job will require a lot more time and effort to get the desired results.

Coarse Grit Sandpaper

Coarse sandpaper has a grit of around 40 to 60 and is generally made from aluminium oxide or ceramic. It’s commonly used for the removal of tough finishes like varnishes and lacquers, as well as the rough shaping of wood. Because of the large particles, coarse sandpaper makes quick work of tough jobs by easily scraping away more of the surface material at one time.

Uses

-

Quickly removing finishes and lacquers

-

Rough shaping of wood

Medium Grit Sandpaper

If you’re looking for a versatile sandpaper, go for a medium, 80 to 100 grit sandpaper made from aluminium oxide or emery. This grit level is ideal for the primary shaping of your surfaces, removal of surface imperfections, and sanding down unfinished wood.

Uses

-

Smoothing down surface imperfections

-

Primary shaping

-

Sanding down unfinished wood for painting

Fine Grit Sandpaper

For most DIYers and amateur decorators, fine sandpaper with a grit of 120 to 220 is ideal. These sandpapers can be made from emery, aluminium oxide, or silicon carbide – the latter of which can be used with water as a lubricant for an even smoother finish. Fine sandpaper is perfect for smoothing walls prior to painting.

Uses

-

Smoothing walls prior to painting

-

Prior to using very and extra-fine grits

-

Sharpening scissors

Very Fine Grit Sandpaper

Very fine sandpaper has a grit between 240 and 400, and anything higher is generally labelled extra-fine. These levels of grit are perfect for sanding between coats of varnish or paint to remove paintbrush strokes and offer an even smoother finish. You’ll find very fine and extra fine sandpaper with different abrasives – including silicon carbide (wet applications), aluminium oxide, and emery.

Uses

-

Very light sanding between coats of varnish or paint

-

Polishing wood, metal, and metal finishes

Key Sandpaper Considerations

Sandpaper Abrasive

Most sandpapers are made from aluminium oxide, emery or silicon carbide. Emery sandpaper is a very coarse abrasive and commonly used for metalwork – it’s often too sharp for softer materials like wood.

Aluminium oxide sandpaper is a versatile abrasive, and even has self-renewing properties – meaning it’ll expose new sharp edges during use instead of getting dulled.

Silicon carbide sandpaper is an ideal material for wet sanding – using water as a lubricant to get an even smoother finish by making the sandpaper less coarse.

Sandpaper Backing Material

Despite what you may think, sandpaper is not always made with a paper backing. Instead, many sandpapers have a cloth or film backing to offer extra strength for any job.

Look out for cotton polyester or rayon backing for dry sanding, and PET film for wet sanding with silicon carbide.

Without the right backing material, the abrasive could become seperated from the backing and ruin your project, especially when using power sanders.

Sandpaper Flexibility

You may also find sandpaper with a letter value which tells you more about the flexibility and durability of the sandpaper.

Flexible sandpaper will make it easier to get into tighter corners, while stiffer, more durable backings will last longer and remove material faster. For paper backings, you’ll find values from A to F – with A-weight sandpapers being the most flexible, and F weight being the least flexible yet strongest.

For cloth sandpapers, you’ll find J, X and Y backings – J-weight being the most flexible, X being stiffer, and Y being the stiffest and most heavy-duty. Film backings are not graded by flexibility.

Open/Closed-Coat Sandpaper

Open-coat sandpaper has larger gaps between the grit particles, which cover about 50% to 70% of the surface. This makes open-coat abrasives more suited to woodworking as it clogs less often – especially if you’re planning to work with soft woods that might contain more resin.

A closed-coat sandpaper has about 90% to 95% of the surface covered with the abrasive. These sandpapers are more aggressive and better suited to harder woods, metals, and for finishing lacquer and sealing coats. For most projects, you’ll probably want a closed-coat sandpaper to start with, and then finish up with an open-coat sandpaper.

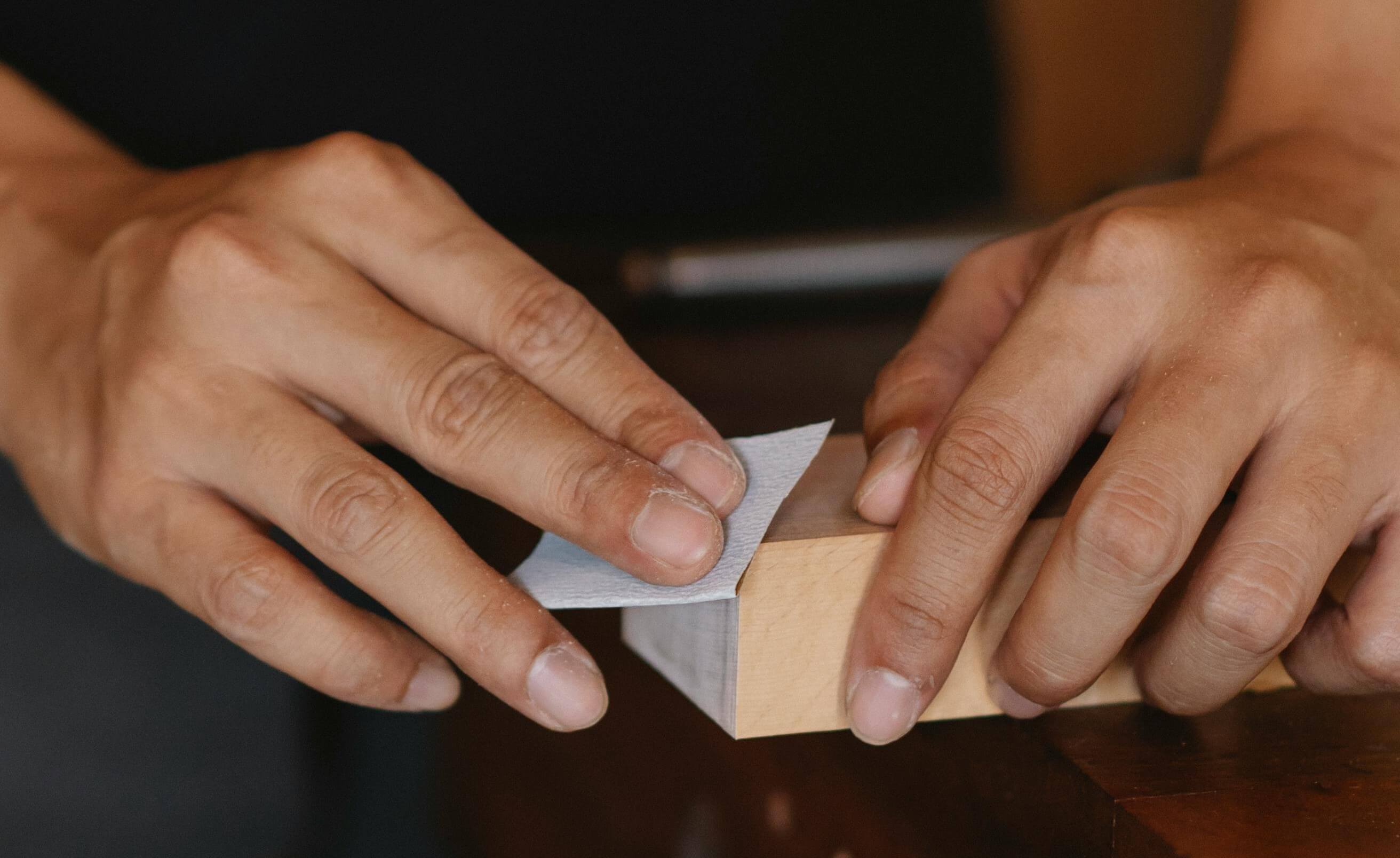

Sanding Tools

Some projects will be just fine with manual sanding using a basic strip of sandpaper or a sanding block. But if you want to get the job done quicker a palm sander, orbital sander or random orbital sander will make light work of your projects.

For intense sanding, a belt sander, bobbin sander or bench sander are perfect. Speciality alternatives such as drywall sanders are ideal for getting a professional finish on plaster. For finishing touches, polishers or detail sanders can get into the edges of surfaces for a professional result.

Workwear & Safety

Whatever you’re sanding, breathing in the dust from the surface can pose a risk to your lungs. Make sure to purchase a face mask or respirator to protect your health and make for a more comfortable experience.

Safety goggles can help protect your eyes from dust and debris. Get kitted out with the appropriate safety wear, as scratches from debris could cause lasting damage to your eyes, including blindness.